Hydrogen oxide flame enameled wire bonding machine introduction:

The high (medium) frequency electric induction heating equipment independently researched and produced by the company is a new technology product completed with international and advanced electronic components and unique technology. It can inductively heat any metal in a non-contact form by penetrating non-metallic substances by the principle of electromagnetic effect.

1: The heating temperature is high. Can melt any metal. Can reach any temperature.

2: Heating speed is fast. There are very few rights layers.

3: High efficiency and energy saving, high energy conversion rate. The power consumption is 1/5 of the old-fashioned tube. The standby state consumes almost no power. And can work 24 hours a day.

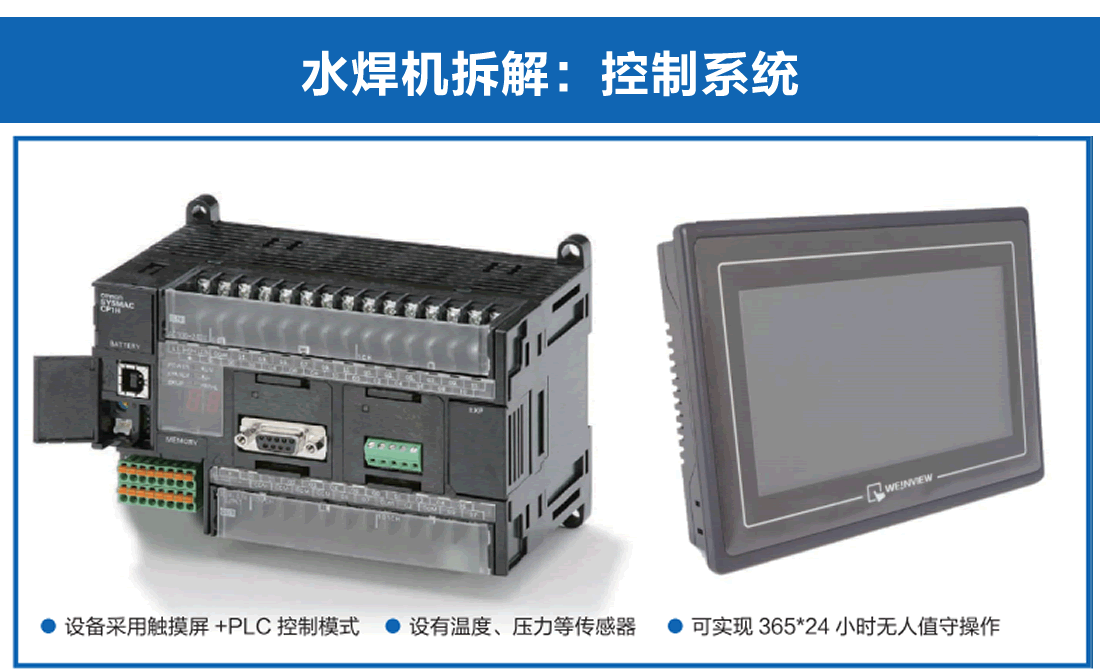

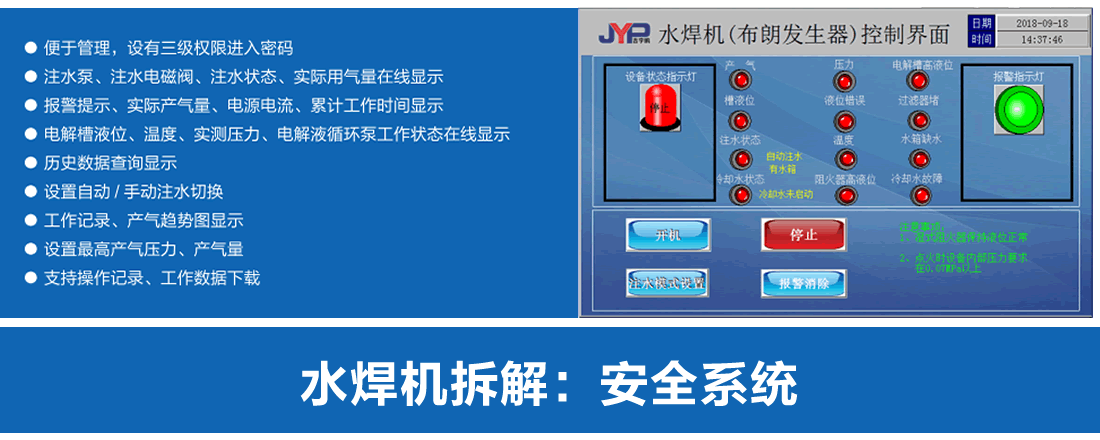

4: Automatic control, can adjust the power and time of heating and insulation process. Conducive to improve the repeatability of heating. Simplify the worker's operating skills.

5: Particularly safe, avoiding the risk of electric shock from pressure. Occupational gas, gas and other dangerous gas heating, unknown fire production. More in line with national safety and environmental protection regulations.

6: Small footprint. It is easy to operate and requires no special training. It can be learned in a few minutes.

7: Installation is simple, just power and water. The induction coil can be freely disassembled. Easy to replace.

8: This unit has automatic protection. Water shortage. Undervoltage, overcurrent. The lack of any of the parameters does not meet the requirements. The machine will automatically shut down and no longer work. With higher reliability and stability.

(1) Suitable for any metal heating, the temperature can reach any temperature you want.

(2) Suitable for welding between metal and plastic, such as: speaker net implant. brush. Daily necessities. Eyebrow brush. Electrical switch welding. Stainless steel tube and plastic summer combination.

(3) Welding between metal and metal (same kind. dissimilar metal welding) such as: turning tool. Create a knife, reamer. drill. According to the film, woodworking knives. Abrasives, faucets. Bathroom products, air conditioning tubes, air pipes, tubing. tool. appliance. Antenna, cable box, dispenser. Rhinestones, etc.

(4) Suitable for tempering various metal materials. Annealing, quenching, quenching and tempering, etc., such as: Drinking utensils. stainless steel. Chuck. thimble. Stainless steel appliances. Tool tempering;

(5) Suitable for quenching various metal materials: gears. Cam. Axis class. tool. Tool. Hardware accessories, auto parts. Travel, industrial supplies, daily necessities. Machining, etc.

(6) Hot forging. Hardware workpieces, standard parts. Case. Spare parts, off the ball head, tools. appliance. And other metal heating molding process.

(7) Smelting. gold. silver. Chin, zinc alloy. copper. steel. Metal such as iron is smelted.

Main specifications: 5KW 15KW 20KW 25KW 30KW 40KW 50KW 60KW 80KW 100KW 120KW, 150KW 180KW 200KW can be customized according to the requirements of the user. The company can provide long-term after-sales service for similar products for new and old customers. And provide technical advice.